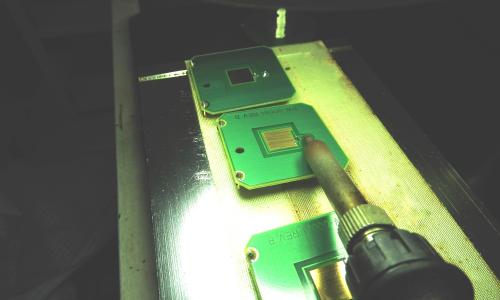

Bell Electronics Die Inspection is carefully examining a die to make sure it is in good condition, meets design specifications, and is free from damage or wear that could affect the quality of the parts it produces.

Services

-

-

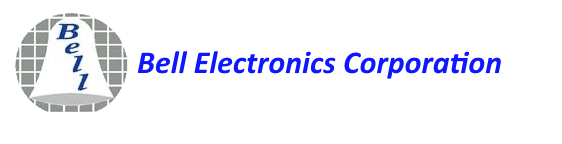

Bell Electronics is using an Automated machine transfering die from Blue Tape to Blue Tape maintaining precision and cleanliness.

-

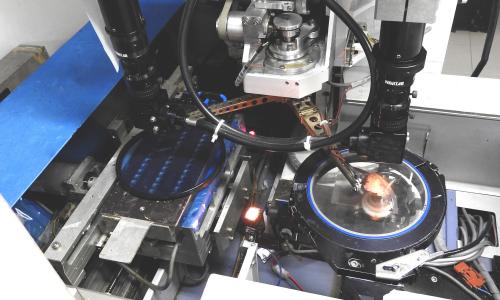

Bell Electronics is using an Automated Machine ensuring careful process of moving semiconductor dies from Blue tape to a soft gel carrier (Gel-Pak) for safe handling, inspection, sorting, or shipment especially for delicate or valuable components.

-

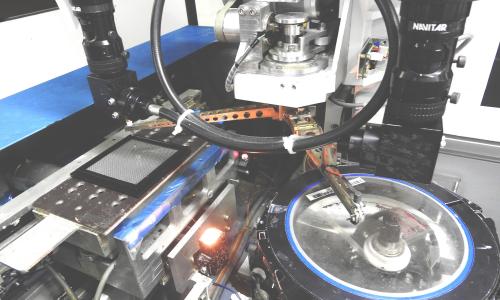

Bell Electronics using a precise Laser Machine for labeling a product for traceability, quality control, and identification throughout the semiconductor supply chain.

-

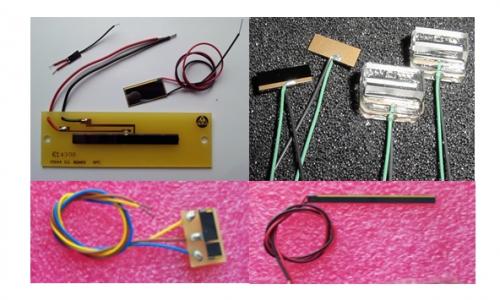

Soldering on a die applying solder directly to the surface of a semiconductor chip to form interconnects, bumps, or attach features like wires or substrates

-

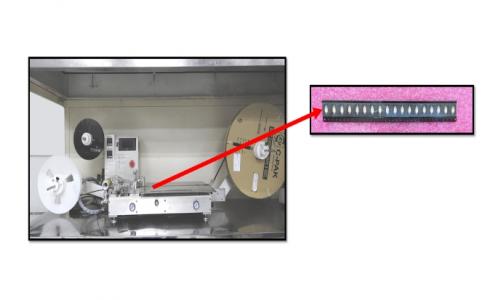

Bell Electronics using a Tape and Reel Machine for safely and efficiently store and deliver surface-mount devices such as ICs, resistors, capacitors for automated pick-and-place assembly in PCB manufacturing.

-

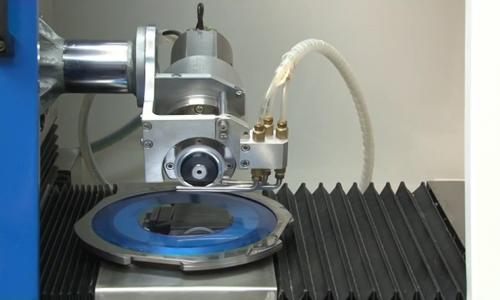

In the context of manufacturing integrated circuits, wafer dicing is the process by which die are separated from a wafer of semiconductor following the processing of the wafer. The dicing process can involve scribing and breaking, mechanical sawing (normally with a machine called a dicing saw) or laser cutting. All methods are typically automated to ensure precision and accuracy. Following the dicing process the individual silicon chips are encapsulated into chip carriers which are then suitable for use in building electronic devices such as computers, etc.

-

Soldering provides reasonably permanent but reversible connections between copper pipes in plumbing systems as well as joints in sheet metal objects such as food cans, roof flashing, rain gutters and automobile radiators.